In fact if the position parameter were a uint16_t and the range 0 to 65535, then all possible input values would be valid and you could pass the output of AnalogIn::read_u16() to it directly so your loop could just contain: output.SetPosition_u16( input.read_u16() ) That way the somewhat arcane output value calculation would be simplified because the Servo class would do that for you with suitable range checks. It would be better if the min/max pulse width were passed to the constructor along with the period so that you could just give it a zero to n set-point rather than an absolute pulse width. Note that this is not the most elegant Servo class implementation. Output.SetPosition( ((set_point * SERVO_RANGE) > 16) // 1 to 2ms The fixed point version would have: uint16_t set_point = input.read_u16() // 0 to 2^16 Wait_us( SERVO_PERIOD ) // wait for one complete PWM cycle. Output.SetPosition( set_point * SERVO_RANGE + SERVO_MIN ) // 1 to 2ms Output.Enable( SERVO_MIN, SERVO_PERIOD ) įloat set_point = input.read() // 0.0 to 1.0 Static const int SERVO_RANGE = SERVO_MAX - SERVO_MIN Static const int SERVO_MAX = 2000 // 2ms in microseconds Static const int SERVO_MIN = 1000 // 1ms in microseconds Static const int SERVO_PERIOD = 1000000 / SERVO_FREQ // microseconds Putting all that together (with a few other refinements): #include "mbed.h" Or uint16_t set_point = input.read_u16() Output.SetPosition( (int)( (set_point * 1000) + 1000 ) // Scale to 1 to 2ms So you need either: float set_point = input.read() Then the Servo::setPosition() function takes a position argument in terms of the pulse width, and as explained above this relates to a position scale 0 to 20000 given the suggested initialisation. Personally I'd use the integer version, but the STM32F4 parts have a single precision FPU, so the lack of hardware floating point is not an issue in this case - although there are other reasons for avoiding floating point. The mbed AnalogIn class has two read functions AnalogIn::read() returns a float in the range 0.0 to 1.0 and AnalogIn::read_u16 returns an uint16_t value 0 to 65535.

#Servo motor arduino potentiometer full

In closed-loop control you continuously: _įinally you need to understand that the units of the input measurement in this case are not the same as the units of the output setting - they need scaling so that the full scale input range maps to the full scale output range.

#Servo motor arduino potentiometer code

Moreover you have an entirely unnecessary inner loop that appears for come from the example code for an entirely different Servo implementation here - that example was not a closed-loop control system - it simply continuously cycles the servo back-and forth over its full range - that is not what you are trying to achieve in this case and it is just cargo cult programming. Here you only read the potentiometer once before the control loop, so in the loop it never changes value so the position will not change. Then you need to understand that a closed-loop control system must continuously read its input to adjust the output.

Then if you want to read an analogue input, clearly you need an AnalogIn object: AnalogOut input(A1) First you need to instantiate a Servo object (which you have done), then you need to Enable it by setting its pulse interval and initial pulse width (or position): Servo output( D6 ) Second you need to read the documentation (in the comments) for the Servo class you are using. The pulse width determines the position, so a width of 1ms will position the servo at one end of its travel, a pulse of 2ms will set the position at the other end, and 1.5ms will set the centre position. From the data sheet it requires a 50Hz PWM with a pulse width from 1 to 2ms. The first thing to understand is how the servo motor works. cpp file in the same place as it so if anyone needs it as a reference I'll post it as an edit. After disabling the servo won't get any signal anymore * StartPos The position of the servo to start (us) Without enabling the servo won't be running. * NewPos The new value of the servos position (us)

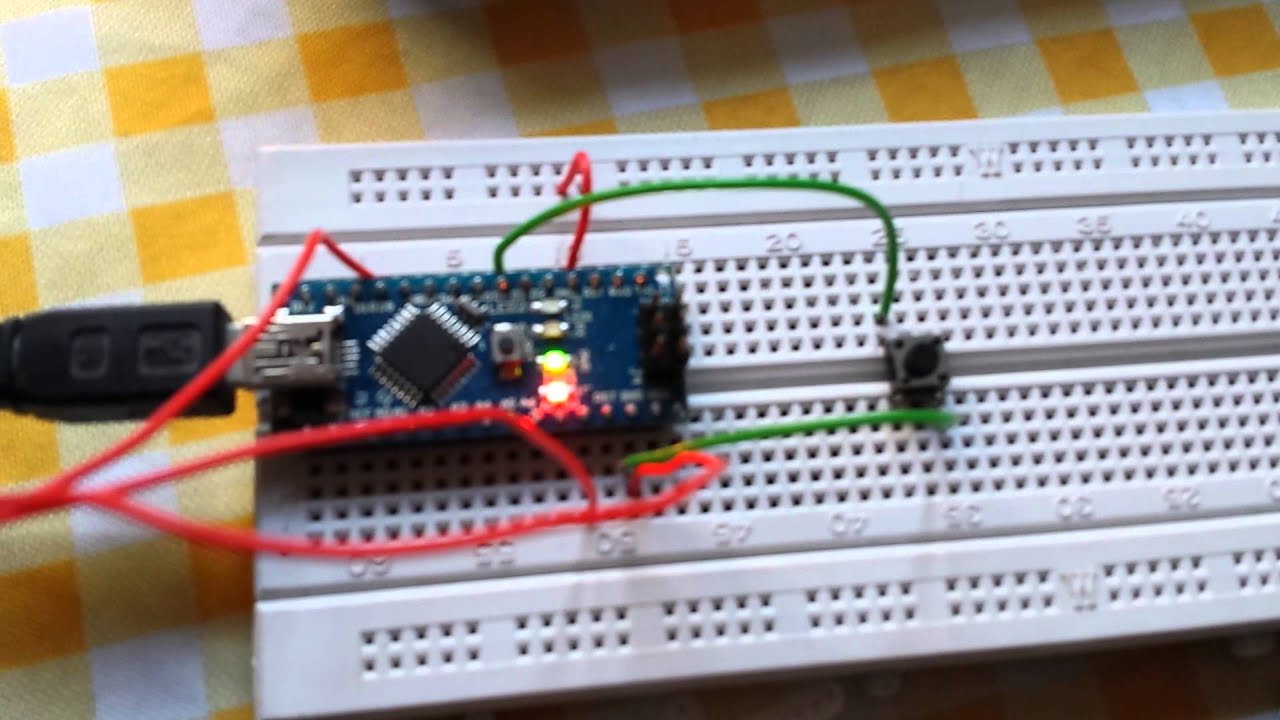

** Create a new Servo object on any mbed pin The board I am using is a Nucleo STM L476RG board and the motor is a micro SG90. If anyone could help or provide some assistance to the matter, it would much be appreciated. When I tried to insert it into the program the servo didn't move at all, and I don't know if it is a result of my board, my wiring, or my code. This code is meant to utilize a potentiometer to turn a servomotor.

0 kommentar(er)

0 kommentar(er)